| Dear Sir or Madam,

|

| Designing sustainable solutions for construction is more than ever the challenge of the coming years and decades. The reality of implementing ecological transformation has shown that ecological solutions always prevail when they are also driven by economic factors. Sheer altruism and an ideology of renunciation will not give rise to a mass movement toward more sustainable solutions. Social sustainability is also becoming increasingly important: hundreds of thousands of affordable apartments are lacking in metropolitan areas, which has already created social tension and envy that could divide society. The only way to counteract this is to create cost-conscious solutions quickly using durable construction methods: Prefabricated concrete components in slim dimensions offer the best solution here: eliminating housing deficits quickly, building more simply yet with high quality. To achieve this, the focus must return to people‘s needs. „Markets for people“ is therefore the motto of the industry‘s leading congress, the 70th BetonTage, which will take place from March 10 to 12 at the CCU Ulm. There, we will discuss sustainable projects with the entire construction value chain. This is a warm invitation to contribute your ideas and provide new impetus with your solutions.

Yours,

Dr. Ulrich Lotz (Managing Director FBF Betondienst GmbH; Organizer BetonTage)

|  |

| | |

|

| |

|

| |  |

|

Figure: TalkConcrete - Digital Services

|

| | | Interview: Digital communication needs new formats |  | Digital communication, new distribution channels, and the use of artificial intelligence are also fundamentally changing the concrete and construction industry. TalkConcrete | Digital Hub, which will take place for the first time on March 11 and 12, 2026, as part of BetonTage in Ulm, is creating a new platform that focuses specifically on marketing, PR, and sales managers. In an interview with BFT ...

|

| » read article

|

|

|

|---|

|

|

|

| |

|

Figure: Kniele

|

| | | Complete renovation of the mixing plant at Fuchs |  | In July 2025, the comprehensive modernization of the concrete mixing plant at the Zeithain precast plant was successfully completed. With its new plant, Fuchs is setting standards in terms of efficiency, precision, and sustainability. The foundation for the project was laid in July 2022 with a precise 3D scan of the tower plant. Detailed planning began in early 2024 with ...

|

| » read article

|

|

|

|---|

|

|

|

| |

| | Good design should not need defending once construction begins. HULCO® Anchor Bolts are designed to perform reliably from drawings to execution. With ETA assessment and certified load-bearing behavior, they provide clarity and confidence for designers and contractors alike. Their slim, compact shape fits easily within reinforcement cages, even in demanding conditions, supporting smooth installation and predictable results. Choose an anchoring solution that works where it matters most.

More information

|

|

| |

|

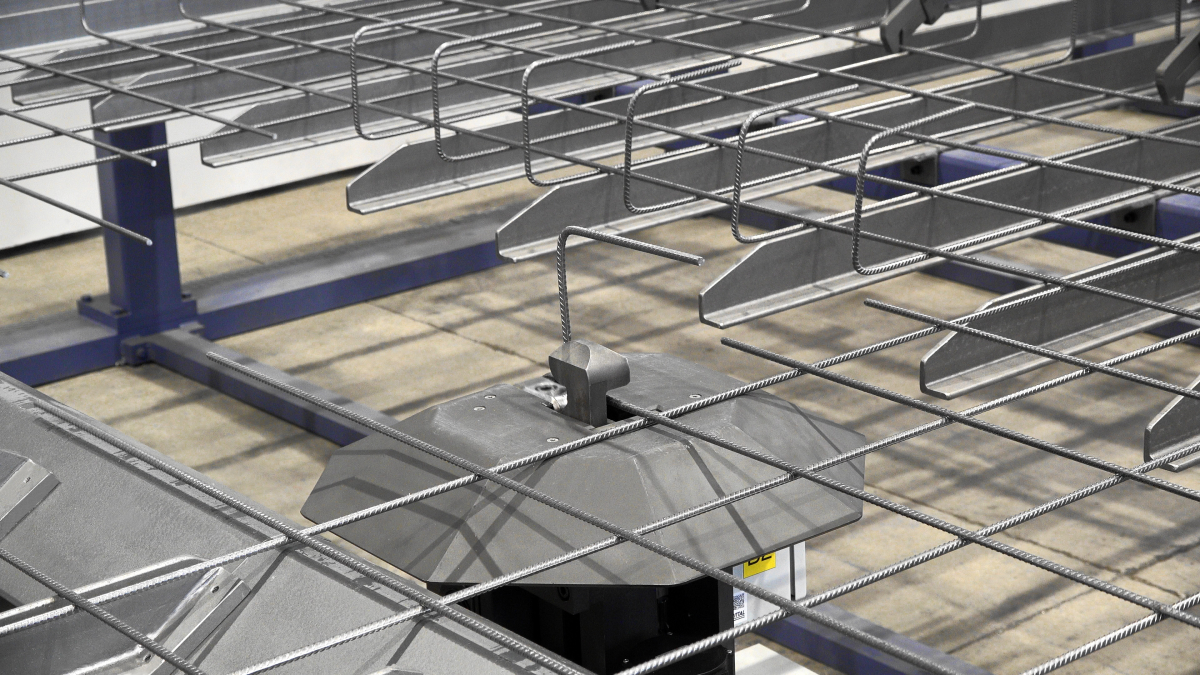

Figure: Progress

|

| | | Pioneering Precast Innovation in Western Canada |  | Western Canada’s precast industry has gained a new driving force: Matbar Industries, who recently partnered with Progress Group to bring cutting-edge automation into mesh production. With the installation of the M-System BlueMesh mesh welding plant, the young company has positioned itself as a pioneer in rebar mesh production across the region ...

|

| » read article

|

|

|

|---|

|

|

|

| |

|

Figure: Fabrino

|

| | | Color for striking architecture |  | Concrete doesn‘t have to be gray. With Rebacolor 8525 Green, Fabrino brings a fresh look to facades, giving them depth and presence. The result is architecture that shows courage, conveys emotion, and sets a clear example for sustainable construction. Green is more than just a color. It is a statement. This commitment is evident in the expansion of the new headquarters of Beton Eisack in Klausen, South Tyrol: Rebacolor 8525 Green gives the facade an expressive, lively surface ...

|

| » read article

|

|

|

|---|

|

|

|

| |

|

Figure: Eurobend

|

| | | Integrated bending modules and mesh bending stations |  | Eurobend GmbH offers a comprehensive line of automatic machines for all precast concrete applications: from entry-level welding machines producing simple reinforcement elements to complex equipment for the production of special mesh, engineering mesh, mesh with openings, mesh with bent line and cross wires and bent mesh into baskets ...

|

| » read article

|

|

|

|---|

|

|

|

| |

|

Figure: Peikko Gulf

|

| | | Peikko Gulf‘s success story in Ras Al Khaimah continues |  | Finnish supplier Peikko celebrated the opening of its new plant, Peikko Gulf LLC, in the United Arab Emirates in February 2020 and has been on a growth trajectory ever since. BFT editor-in-chief Silvio Schade recently visited the Company to see for himself. It now has another branch in Dammam, Saudi Arabia, called Al Khobar, which employs ten people ...

|

| » read article

|

|

|

|---|

|

|

|

| |

|

Figure: Sönke Tunn

|

| | | Pyrolysis and optimized concrete curing |  | Rising energy costs and the need for sustainable resource utilization are two major challenges the concrete precast industry is facing. This article concentrates on the concrete products sector to explain how combining state-of-the-art curing systems with decentralized energy generation through pyrolysis can reduce carbon emissions without jeopardizing product quality ...

|

| » read article

|

|

|

|---|

|

|

|

| |

|

|

|

Figure: Masa

|

| | | Quality assurance as an integral part of the intelligent Masa plant control |  | More than control – true process intelligence: By fully integrating optical quality control into the Masa plant control system, a solution has emerged that not only monitors quality but helps ensure it and sustainably increases efficiency. Fully automated, optical Quality control systems are becoming increasingly established in the block and paver manufacturing industry. However, Masa is going one step further with its system introduced in 2025: the combination of high-resolution image processing, 3D surface inspection ...

|

| » read article

|

|

|

|---|

|

|

|

| |

|

| |  |

| | Suggest your project involving precast concrete products for an exclusive report published in the BFT magazine, free of charge |  |

|

| You have completed a construction project with precast concrete products successfully and now, you intend to present this project to your customer base, prospective customers and partners in the BFT trade magazine? Then, send us an email shortly describing the project. Or just call us. If the project is of particular interest to our readers, our editors would even like to pay you a visit for preparing an exclusive coverage for the BFT magazine in close coordination with you. Our service in this regard is free of charge.

|

|

|

|

| |

|  | | Silvio Schade |  |

|

| |

|

|

| |  | | Karla Knitter |  |

|

| |

|

|

|

|---|

| |

|  |